Importadora Alsacia Spa, a leading company in distributing automotive spare parts, has significantly transformed its operations in recent years. In response to market changes and customer demands, the company has adopted a proactive approach to measurement, continuous improvement, and innovation in its processes.

Their business model is exclusively through an online sales channel. Customers, who are themselves distributors, place their orders through the e-commerce platform on the website, which updates every 3 minutes, automatically showing availability. Once placed, the orders are sent to the Enterprise Resource Planning (ERP) system, from where they are transmitted to the Warehouse Management System (WMS) for proper processing.

Infor WMS is a cloud-based Warehouse Management System that supports the optimization and management of resources in a warehouse. Among its advanced features is a module called Labor Management, which manages activities and productivity based on labor standards. In line with its digitalization project, Alsacia implemented this module and has achieved great success. In this article, we will share the results they have achieved so far.

Order Optimization: This is How Part of Their Operation Works.

When customers create their order, the order waves are processed and sent to production through communication interfaces or held for accounting and payment analysis. Orders that proceed to the production phase are prioritized according to business rules and stock availability through ABC classification algorithms. The operators, currently totaling 112 people responsible for handling the merchandise and using the system, simply log in to their workstations, make themselves available, and proceed to prepare the orders.

In Search of an Exceptional Level of Service.

In recent years, the company faced a significant challenge: a lack of visibility in its operations and a suboptimal level of service. To address these challenges, the company set out to improve its operational efficiency and optimize its internal processes.

«A year and a half ago, the decision was made to focus all business processes on improving the level of service. That’s when the labor digitization project was launched, along with the implementation of the S&OP module, conceived as a fundamental ally in this endeavor. The focus was especially on supporting the sales and operations areas, with the goal of driving continuous improvement in the level of service.«

—Elvys Betancur, IT Manager.

¿What were the first optimization steps in that digitalization plan?

The first step was to measure the starting point of the company in relation to the level of service. This analysis revealed a 54% indicator. With this knowledge, the challenge was now to find ways to improve this metric and identify key areas to achieve it. Subsequently, tasks that were being performed manually and could be automated were identified. For example, in various areas, order releases were requested, but the order planning manager was not meeting the necessary requirements to ensure timely fulfillment, which in turn affected customer satisfaction.

«One of the key elements was to include a Kraljic Matrix within the methodology, allowing each area manager to list all the activities to be addressed (according to business objectives), identifying those with high impact and high performance that could be resolved promptly, creating a win-win situation for both their internal operations and the business.»

—Elvys Betancur, IT Manager.

At that point, the digitalization of the outbound order launch process began. An algorithm was used in conjunction with communication interfaces between an accounting system and Infor’s WMS. The technological advancements available at the time were leveraged to ensure that each area could effectively handle these orders.

The results of the Labor Management System were immediate.

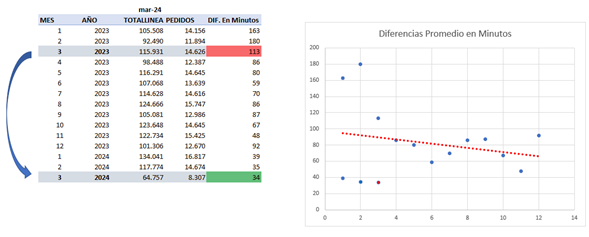

With the implementation of Labor Management, the company achieved significant results. First, the service level improved from 54% to 72% and then to 84%. This improvement contributed to the process from receipt to storage being oriented towards reducing preparation time. Currently, the company has a preparation environment close to 90%, and supervisors can now more accurately identify which employees are the most efficient.

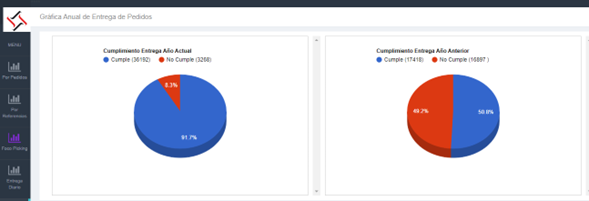

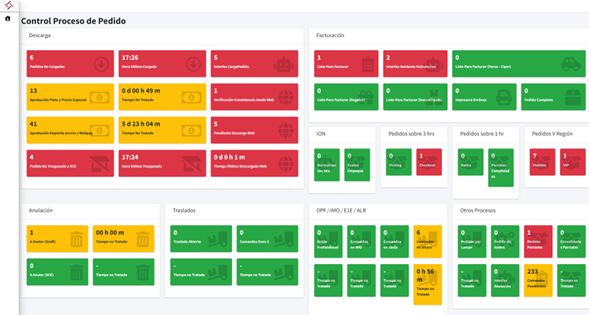

Real-time visual tracking part of On Time, example for the current March – Previous Year’s Period:

Additionally, it became possible to visualize where the workload was accumulating and the efficiency with which the team handled tasks. This allowed for the definition of performance indicators that would help measure and demonstrate the improvements from the digital transformation project.

Some of the most representative indicators of this implementation are:

- 50% reduction in order preparation time, from 6 hours to 3 hours.

- +30% increase in service level.

- The preparation environment is close to 90%.

- A fill rate of 99.84% is maintained.

- Real-time visibility of operator efficiency was achieved.

- Downtime in operations was reduced.

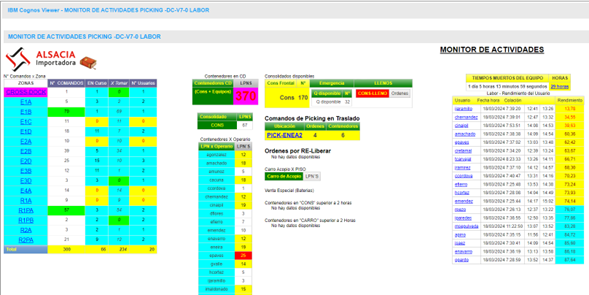

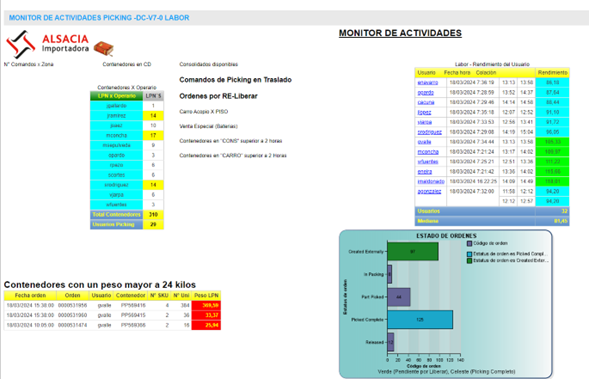

Dashboard part for Labor and picking workload by zones (command tracking):

Result of the tracking for consolidation (comparison from March 2023 to March 2024, from an average of 113 minutes to an average of 34 minutes):

Increase in sales as a result of the improved service level. Previously, customers would request a single spare part, but now, due to complete and timely deliveries, the number of orders or references per order has increased.

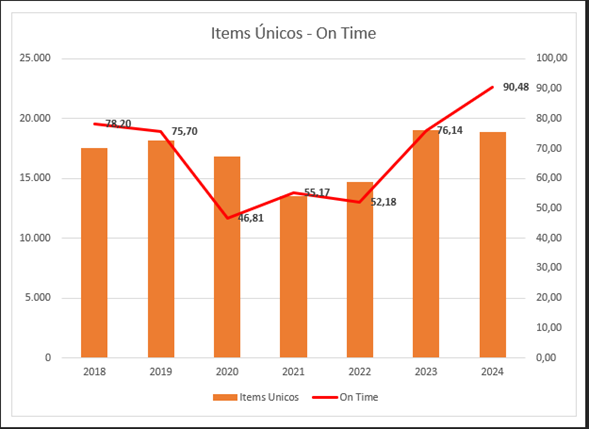

Statistics on Unique Items versus the improvement in service level:

Dashboards: The comprehensive view that the operation aimed for from the start

To involve the CeDi team in meeting these new objectives, the company implemented screens that display orders, tasks, assigned personnel, and priorities using a “traffic light” method with color codes to indicate priorities for the operators to consolidate orders. Once all orders are consolidated and complete, the picking phase begins. Previously, this practice did not exist, as merchandise was received and checked without having the complete order.

Thanks to these dashboards, it is now possible to measure each operator’s efficiency, providing a complete performance map. Performance indicators are rewarded with incentives, which has led to a significant change both organizationally and culturally.

With support from other areas, orders with issues were identified and the time needed to resolve them was reduced, representing a major benefit. In this regard, order launching was automated, and slotting was optimized to improve preparation. Additionally, the main goal was continued: maintaining the service level as a priority within the company.

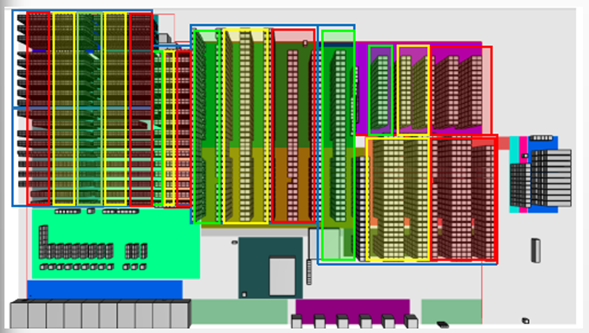

Application of slotting, physically (Green A, Yellow B, and Red Zone C):

The dashboards notify when the next phase of the receiving process begins, allowing the responsible teams to quickly define the location of stored products. Additionally, tools such as Teams and Office 365 Planner have been integrated to facilitate coordination between different departments. Thanks to these improvements, teams can plan the receipt of imports more efficiently, ensuring that products are available for sale in the shortest possible time.

Eliminating downtime and optimizing operational resources.

In addition to all the benefits and achievements previously mentioned, the Labor Management System helped identify and utilize periods of inactivity for warehouse operators. This allowed the company to assign additional tasks, such as organizing products, arranging storage space, and performing labeling tasks, thereby maximizing productivity during the workday.

With the tool, business rules can be configured so that when an operator finishes their work phase, they notify that they are available. This allows the supervisor to identify who is free and without pending tasks. It also helps identify those who have not logged their inactivity, as the system stops time tracking according to average standards, showing the period in which a person has been inactive without notifying. This setup not only improved operational efficiency but also helped optimize the use of time and available resources in the distribution center.

Storage Intelligence: The Company’s Future Plans.

In the future, the company aims to consolidate intelligence in storage. In addition to maintaining operational excellence in line with business strategies, «It is essential that this process reaches a level of maturity where it does not rely solely on a few individuals,» says Elvys Betancur, IT Manager.

The company expects that, unlike the current approach based on algorithms using ABC classification, machine learning will be employed to identify which new products could benefit from the best location, based on similarities and behavioral patterns, all through Machine Learning.

You might be interested in reading: